Also known as hypromellose, is a versatile and widely-used non-ionic cellulose ether that is derived from natural polymers such as refined cotton or wood pulp through a series of chemical processes. HPMC is a methyl cellulose ether derivatives polymer and exists as an odorless, non-toxic, and tasteless white powder. It can dissolve in hot and cold water to form a transparent viscous solution which has a range of properties that make it highly desirable for use in a variety of applications. HPMC has excellent thickening, binding, dispersing, emulsifying, film-forming, suspending, adsorbing, gelling, surface-active, water retention, and protecting colloid properties. It is widely used in different industries such as construction, pharmaceuticals, food, PVC, ceramics, and personal/home care products. In the construction industry, HPMC is frequently utilized as a thickener for drymix mortars, tile adhesives, water-based paints, wall putty, thermal insulation mortar series. In addition, it is employed as a pharmaceutical excipient and food ingredient, as well as in the production of PVC, ceramics, and detergents. Textiles, personal care products, and home care products also commonly contain HPMC as an ingredient.

Types of Hydroxypropyl Methylcellulose

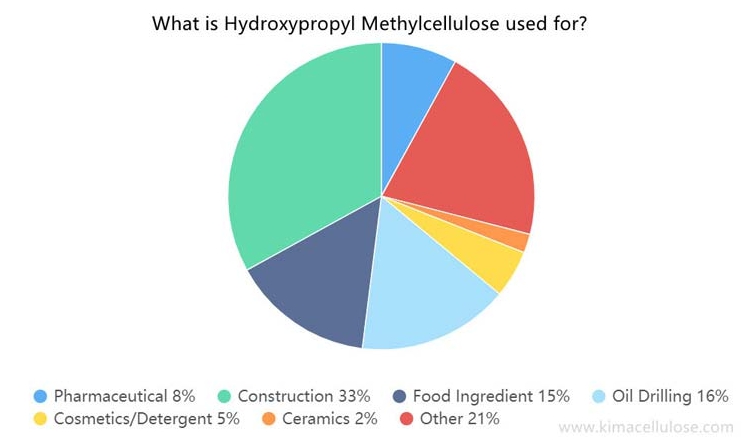

What Is Hydroxypropyl Methylcellulose Used For?

HPMC is obtained from natural sources like cotton and wood pulp. The process involves alkalizing the cellulose to obtain it, and then adding propylene oxide and methyl chloride for etherification, which leads to the production of cellulose ether.

HPMC is a versatile cellulose ether used in numerous industries as a thickener, stabilizer, and binder, among others. Its widespread use includes construction, pharmaceuticals, ceramics, and food, among others.

YibangCell® HPMC is a highly versatile and eco-friendly additive, offering a range of benefits such as wide application, minimal usage per unit, effective modifications, and enhancing product performance. Its addition improves resource utilization efficiency and the value of products. It is an essential environmentally-friendly additive in various industries.

1. Pharmaceutical excipient:

Hydroxypropyl Methylcellulose (HPMC) is a vital ingredient in pharmaceuticals, enabling sustained & controlled release drug preparations, tablet coatings, suspending agents, tablet binders, and disintegrants in various drug delivery forms, such as vegetable capsules. Its versatility and broad usage range make it a crucial excipient in the pharmaceutical industry, enhancing drug efficacy, and improving patient experience. Additionally, HPMC is eco-friendly, sustainable, and cost-effective, which makes it an ideal choice for developing pharmaceutical products.

2. Food Ingredient

Hydroxypropyl Methylcellulose (HPMC) is a safe and versatile food additive used worldwide as a thickening, stabilizing, and moisturizing agent to enhance taste and texture. It finds extensive applications in baked goods, sauces, whipped cream, fruit juices, meat, and protein products. HPMC is widely accepted and approved for food use in many countries, including the United States, China, and the European Union. Overall, HPMC plays a crucial role in the food industry's success by enabling improved shelf-life, taste, and consumer appeal of various food products while maintaining high safety standards.

This paragraph discusses the current situation in China regarding the use of Hydroxypropyl Methylcellulose (HPMC) in food production. At present, the proportion of food-grade HPMC used in China's food industry is relatively low due to the high price and limited application. However, with the steady growth of the food industry in the long run and increasing awareness of healthy food, the penetration rate of HPMC as a health additive is expected to gradually increase. The use of HPMC can improve different products by enhancing their stability, texture, and shelf-life. Thus, it is expected that the consumption of HPMC in the food industry will grow further in the future. This can lead to increased innovation and development in the food industry to keep up with changing consumer preferences and demand for healthier, high-quality food products.

3. Construction drymix mortar

This paragraph explains the various applications of Hydroxypropyl Methylcellulose (HPMC) in the construction dry-mix mortar industry. HPMC is widely used as a water-retaining agent and retarder, which enables the mortar to remain workable and pumpable for an extended period. It also acts as a binder, improving spreadability, and prolonging the working time of building materials like plaster, putty powder, and other similar products. HPMC is also useful in paste tile, marble, and plastic decoration, providing reinforcement and reducing the amount of cement required in the process. With excellent water-retaining properties, HPMC enhances the strength of the mixture after hardening and prevents the slurry from cracking due to drying too quickly after application. Overall, HPMC is an indispensable ingredient in the construction industry that fulfills various requirements, such as enhancing workability and optimizing the properties of the final product.

How Do You Use Hydroxypropyl Methylcellulose?

First Method

Due to the compatibility of HPMC, it can be easily mixed with various powdered materials such as cement, stone talc, and pigments to achieve the desired performance.

1. The first step in using HPMC is to mix it with all the other ingredients until it is fully dry mixed. This means that the HPMC should be mixed together with the other powdered materials (such as cement, gypsum powder, ceramic clay, etc.) before adding any water.

2. In the second step, an appropriate amount of water is added to the mixture, and it is kneaded and stirred until the compound product is completely dissolved. This step ensures that the mixture becomes a uniform paste that can be easily applied to the desired surface.

Second Method

1.The first step involves adding a certain amount of boiling water to a stirred vessel with high shear stress. This helps to break down the HPMC particles and ensure they are evenly dispersed in the water.

2.In the second step, the stirring should be turned on at a low speed, and the HPMC product should be slowly sieved into the stirring container. This helps to prevent lumps from forming and ensures the HPMC is evenly distributed within the solution.

3.The third step involves continuing stirring until all particles of the HPMC product are soaked in the water. This process ensures that the HPMC particles are fully wetted and ready to dissolve.

4.In the fourth step, the HPMC product is left to stand for natural cooling so that it can dissolve completely. Afterward, the HPMC solution is fully stirred before use. It is important to note that an antifungal agent must be added to the mother liquor as soon as possible.

5.In the fifth step, the HPMC product is slowly sifted into the mixing container. It is essential to avoid adding a large amount of HPMC product that has formed lumps directly into the mixing container.

6.Finally, in the sixth step, other ingredients in the formula are added to complete the preparation of the finished product.